Articles

English

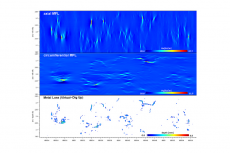

Pipeline Integrity Assessment Applications By Using Vibroacoustic Technology

Asset integrity and operation reliability are primary objectives in pipeline management, nevertheless they require often costly methods, system and procedures. The vibroacoustic technology, developed by Eni S.p.A to detect impacts and spillages on Oil & Gas pipelines, already proved to be able to detect illegal tapping precursor events, and…

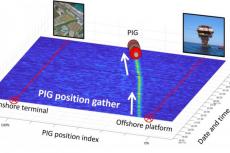

Real-Time Gauge Positioning And Inspection During Pigging Operations In Gas Pipelines

This paper presents a procedure for continuous real-time positioning and tracking of a Pipeline Inspection Gauge(PIG) travelling within a pipeline, by exploiting the pressure transients it generates during the displacement. In fact, the PIG produces recognizable sounds when crossing the welding dents and while sl iding against the pipe walls. This…

The Impact Of Geohazards On The Trans Anatolian Natural Gas Pipeline Project - TANAP

The routing of a pipeline is one of the most critical but often underrated activities in establishing a pipeline and has a direct impact on all aspects of building the pipeline – design, construction, operation, maintenance and most importantly on the overall cost of the pipeline.

A key element which governed the route and design of the Trans…

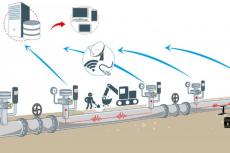

The Integrated Solution of Distributed Acoustic Sensing, Fibre Optic Technology with Unmanned Aerial Vehicles (UAVs) For A Rapid Response To Protect Pipelines.

When a pipeline comes under threat from criminal intent on stealing product by hot-tapping, a rapid and precise response is required to prevent the crime before damage can be done that results in spillage and costly clean-up.

Distributed Acoustic Sensing (DAS), uses fibre optic cables which are already in place alongside most pipelines for…

Zero Harm As An Achievable Target - How To Build A Journey Towards Zero For People, Significant Impacts On The Environment And The Community

NTS is committed to ensuring everyone return home safely at the end of each day, and that our assets are operated in a safe manner. This commitment to safety is based on caring for employees, our contractors, the communities in which we operate and the environment.

We are certain that Zero Harm is an achievable target and for this we focus on…

Editorial 6-2019

The pipeline community do not usually think in terms of individual years - the projects are usually too long-term for that. But some individual years are special. 2020, for example, will be interesting in various respects.

On the one hand, legal disputes about specific projects are moving into the next round. Coastal GasLink, for example,…

Are we filling the pipeline with a capable “Next Generation Workforce?”

“For the first time in the history of mankind, there are four generations in the workforce. There are 35 million Traditionalists (Silent Gen) and 84 million Baby Boomers, the largest number of workers, which began to retire in 2010-11. There are 68 million Generation Xers and 79 million Generation Yers (Millennials as they are better known).…

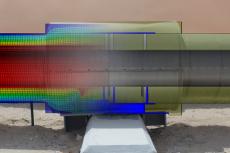

Calculation of a laser-scan-like 3D defect profile from conventional MFL data

Calculation of a laser-scan-like 3D defect profile from conventional MFL data – For more-accur ate defect assessment and prediction of safe operating pressure.

Reliable pipeline safe pressure prediction is increasingly required. Complex shaped volumetric metal loss is a challenge in this regard. Methodological In-line Inspection (ILI)…

Over-Voltage Protection on Pipelines

Pipelines are commonly exposed to over-voltage conditions created by AC faults, lightning and induced AC voltage from high voltage power transmission lines. To protect personnel and the pipeline from the hazardous effects of these conditions, it is critical to properly ground the pipeline and provide continuity across isolation joints for AC and…

Editorial 5-2019

It was not surprising that both chambers of the U.S. Congress signed a bill that will put sanctions in place against some companies that are currently working to finalize the much-disputed Nord Stream 2 pipeline. The pipeline will still be completed, though, because Russia already made clear that it will replace every company necessary that is…

Advanced Detection Technologies and Collaborative Information Systems for Leak Detection and Response

A recent newcomer in the global energy mix, natural gas will represent the second biggest share after oil by 2040 , according to the International Energy Agency (IEA). Demand on natural gas is rising globally with the economic growth of developing countries and the significant move from coal to gas initiated by governments to meet the challenge of…

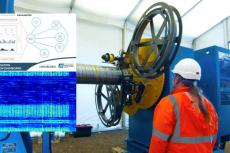

Digital Pipeline Integrity with Spiral Wound Pipe

Interest in using digital systems for pipeline integrity management are growing and the potential both for cost saving on time based manual inspection and for improved real time data is huge.

A onshore new pipeline system, MASiP, (Mobile Automated Spiral Interlocking Pipe) has been developed that incorporates spiral wound optical fibre as a means…

Pipeline Leak Detection via Machine Learning

As physical entities, pipelines are subject to numerous points of failure including corrosion, mechanical damage, and natural hazards. Despite being infrequent, pipeline failure can have disproportionate consequences resulting from environmental clean-up and lost production. Best practices in pipeline risk management employ both leak-prevention…

Editorial 4-2019

You have certainly noticed it already: the ptj now looks different than before. This is the result of an extensive improvement process to which we have committed ourselves in order to provide the international pipeline community with even better content. Of course, the appearance plays only the smallest part, even if it is the most conspicuous at…

©Shutterstock.com/ Inked Pixels; katatonia82

Pipelines may observe significant axial displacement or force at the ends that tie-in with connected equipment and/or facilities. These axial forces are mainly driven by pipe size, temperature, pressure, length and surrounding soils or supports, and can have devastating effects on connecting facilities if not properly accommodated in the design.…

Current View of Design and Evaluation of Sulfur Pipelines

The global production of natural gas is increasing continuously leading to development of gas fields with challenging contents such as sour gas containing highly toxic hydrogen sulfide. In a process called “gas sweetening” the hydrogen sulfide is removed, yielding liquid elemental sulfur. This substance is not just a by- product of the natural gas…

© LogIC

Pressurized fluid transport structures are subject to regulatory obligations for which the system operators must ensure compliance with the administration. In order to meet the obligations and ensure safety of the networks, in addition to the regulatory documents, the managers demand from the holders of laying contracts, the provision of documents…

River crossing and water crossing survey by airborne bathymetric laser scanning - Case study TAG

Airborne bathymetric laser scanning delivers the same results as regular airborne laser scanning, but with one major difference, this technology is able to penetrate water. The technology has matured through the past years, meanwhile it is used for the bathymetric survey of lakes, harbors, coastal shore lines and rivers.

The Trans Austria…

Editorial 3-2019

Each year at DNV GL we produce a report which is an industry benchmark study on the outlook for the year ahead in the oil and gas industry. The 2019 report, ‘A test of resilience’ is based on a global survey that incorporates the views of 791 senior industry professionals.

Our survey found that digitalization is comfortably the leading R…

GAIL (India)

Scenario of oil prices fluctuations has not only forced inefficient Oil & Gas companies to improve their productivity and supply chain costs, but it will also push the efficient companies to find ways to protect their top & bottom lines. A set of new digital technologies such as Internet of Things (IoT), Industry 4.0 promises to aid Oil…

New Technologies Drive Operational Performance by Connecting Smart Stations to Distribution Networks

Emerson

Natural Gas distribution companies have been historically slow to adopt new technologies, especially so-called “Smart” technologies, in their networks. Their counterparts in electric utilities, process plants, and even gas transmission have widely adopted connected components and solutions to quickly give them access to data to make decisions,…

Honeywell

There are approximately 4 million miles of pipelines spanning some 120 countries across the globe, carrying oil, gas and other potentially volatile liquids and gases. The pipelines cross deserts, oceans and some of the most inhospitable environments known to man.

Honeywell have provided control systems for pipelines for over 30 years, and now we…

COGA

In recent years attacks against information infrastructures have become ever more frequent and complex, while at the same time perpetrators have become more professional.

Every day the mass media around the world releases news related to cyber activities, which report the attempts of one country trying to get advantage over another country using…

Arundo

The massive growth in Permian production further underscores the role Midstream companies play in the Hydrocarbon value chain. A lack of processing facilities and pipeline capacity adversely impacts the value of E&P onshore pure plays. The access to markets is curtailed for these E&P companies by lack of capacity to process and…

Satelytics

Benefiting from the vast capacity and speed provided by cloud computing, remote sensing technology is quickly expanding from infrequent projects to becoming an integral part of on-going operations.

We have seen many innovative applications in this arena, particularly at oil & gas, pipeline, and power companies, where their large spatial…