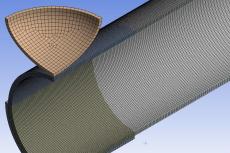

Robust Ultrasonic Transducers for Pipeline Inspection

Robust Ultrasonic Transducers for Pipeline Inspection

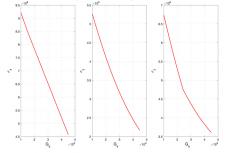

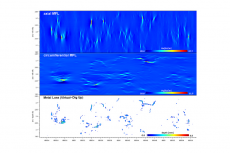

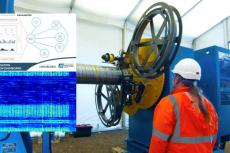

Pipeline inspection for cracks and corrosion through intelligent inline tools relies on ultrasonic probes, demanding a 100% first-run success rate to minimize costs. These probes face harsh environmental conditions within pipelines, necessitating utmost stability for optimal functionality. Material selection and rigorous testing during development...