Real-Time Gauge Positioning And Inspection During Pigging Operations In Gas Pipelines

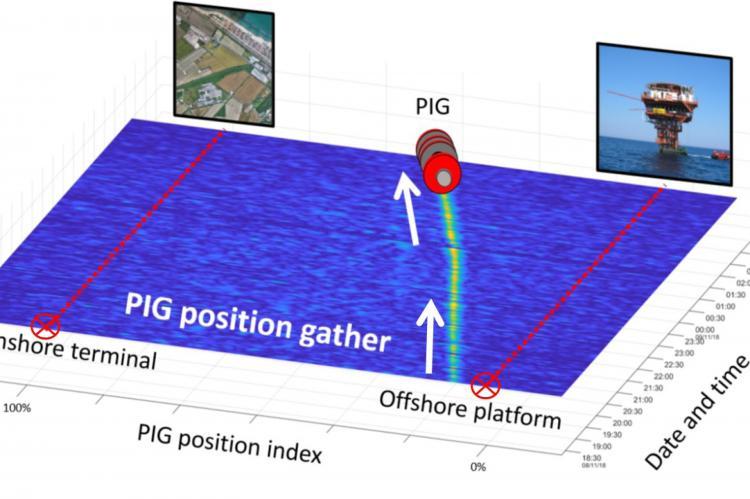

This paper presents a procedure for continuous real-time positioning and tracking of a Pipeline Inspection Gauge(PIG) travelling within a pipeline, by exploiting the pressure transients it generates during the displacement. In fact, the PIG produces recognizable sounds when crossing the welding dents and while sl iding against the pipe walls. This acoustic signature propagates in both directions along the conduit and it can be recorded by sensors (i.e. static and dynamic hydrophones), at least one on each side of the PIG, in order to locate the gauge. The sound can be also processed to detect pipe branches, local diameter reductions, valve crossings, obstruction buckles. The paper analyzes the acoustic signals collected during a PIG campaign at the terminals of a 10” internal diameter, 57300m long gas pipeline, from Barbara A platform in the Adriatic Sea to the onshore station in Falconara (Italy). Several PIGs (e.g. clean up, geometrical, intelligent devices, and brushes) have been transferred from the offshor e terminal to the onshore one, driven by gas flow. During the insp ections the pressure transients received at the acquisition units are cross-correlated in moving windows, revealing a peak that cor responds to the differential propagation time between the “noisy” tool and the recording stations. By tracking the cross-correlation acoustic peaks versus time, it is possible to identify the position of the tool and its velocity. Delay time is converted to absolute distance using the sound velocity in natural gas. The results demonstrate a good accuracy in both detection and tracking. Moreover, the recordings of the differential pressure profiles between the two sides of t he PIGs have been displayed versus pipeline coordinate and overlapped, revealing an interesting similarity: the differential pressure variation peaks can be associated to pipe branches, dents, pipe diameter variations and slopes of the submarine line. The presented PIG tracking technique has the advantages of not requiring additional tools mounted on the gauge, although permitting a real time and remotely controlled monitoring.