Articles

English

Multidisciplinary landslide assessment – a systematic and practicable approach for pipeline projects

Multidisciplinary landslide assessment – a systematic and practicable approach for pipeline projects

Ground movements, with the clear majority being landslides, hav e caused several pipeline incidents worldwide in recent years. This, and experiences obtained from major engineering projects, shows that a systematic approach for the assessment of landslides is essential. A best-practice multidisciplinary workflow, based on detailed terrain analyses…

Overcoming the Challenges and Increasing Value in Fiber Optic Monitoring

Distributed fiber optic sensing has been gaining significant momentum in pipeline industry adoption. The primary application of this technology has been in p reventative leak detection, but intelligent new applications such as pipeline flow rate monitoring are now emerging and promise to deliver extra value to the pipeline operators.

We present a…

Safely repairing subsea flanges on flexible flowlines with a flexible bridging jumper structure

As offshore pipelines age, the oil and gas industry must properly maintain equipment to prevent leaks. In subsea flowlines, leaks sometimes originate from aging flanges. These flanges must be replaced. Historically, replacing the flange has required a lot of time. Different costly approaches are available, from subsea reparations to flowline…

Surge protection for insulating joints – suitable spark gaps and evaluation of the installation

Insulating joints are used for the electrical separation of pipeline systems or for dividing pipelines that are affected by high voltages into sections. The electrical isolation of cathodically protected systems is maintained until the dielectric strength/ flashover strength of the insulating joint is reached. Overvoltages which occur as a result…

ptj-2-2020 Editorial

Today you receive the 2nd edition of ptj, with which we publish the presentations of the “Pipeline Technology Conference”, ptc, which was cancelled due to the corona epedemia. The third special issue with the remaining 20 papers will be published soon.

The online ptc 2020 as a replacement has brought a surprisingly positive response. The…

Cost-effective Ultrasonic Inspection of Large Diameter Pipelines: Technology Update

To be successful in the ILI business, organization require the right mix of technological capabilities, operational agility and quality standards. The business is fairly competitive, and often technological capabilities are pivotal in the customer proposition of the company. However, the best technologies are not solely required for successful ILI…

Enhancing Energy Efficiency and Reducing Greenhouse Gas Emissions through Innovation and Renewables Integration

Consequences of global warming on Earth’s climate are one of the greatest challenges worldwide faced, particularly by industry players. To effectively reduce the amount of greenhouse gas emissions, it is necessary to increase efficiency and exploit renewable energy sources.

Baker Hughes (BH) developed technologies to reduce CO2 emissions and…

GRP Piping Failures

Glass-fibre Reinforced Plastic pipe (GRP) systems, also known as FRP pipe systems, have been succ essful in the world’s markets for more than 50 years. During this time, they have developed into a modern pipe material that is predominantly convincing thanks to its lightweight, corrosion resistance, a smooth inner surface, and easy installation.…

North Sea Wintershall Dea Case Study

Mittelplate is the largest oil field in Germany, located in the environmental ly sensitive Wadden Sea of the German State Schleswig-Holstein. An artificial Drilling and Production Island, named “Mitt elplate A” (MPA), was build early 1980`s on a tidal shoal and is operated by Wintershall Dea.

In 2005, a 10 km, 10” stainless steel (1.4462 Duplex)…

OMEGA Fiber Optic Monitoring System: New Features for Technological Security of Transneft Pipelines

Since 2009 the OMEGA Company develops and produces multifunctional monitoring systems for extended facilities indicating in online mode oil, oil products and gas leaks as far as third party activity in the protected zone using a fiberoptic cable (FOC) as sensing element. Imp lementing distributed acoustic and temperature sensors the Leak Detection…

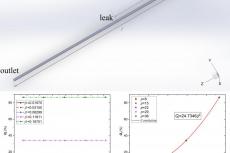

Prediction of Leak Mass Rate in High-Pressure Gas Pipeline

Gas pipeline leakage poses great threat to the environment pollution and system security. The gas leak mass rate is a key index in the assessment of risk level during pipeline leakage. In this study, compressed air flow in a high-pressure pipeline with leakage is considered, and the leak mass rate is investigated experimentally and numerically.…

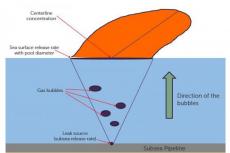

Quantitative Pipeline Risk Assessment (QPiRATM) Fire and Dispersion Analysis of a Subsea Gas Pipeline Leak Using Empirical Consequence Modelling

A subsea pipeline transporting gas in Malaysia has a smal l leak at its subsea flange at 70m water depth, located 140m away from the processing platform. The flange has undergone three rectification works; however, the repair works were unsuccessful to achieve zero leak. A Quant itative Pipeline Risk Assessment (QPiRATM) fire and dispersion…

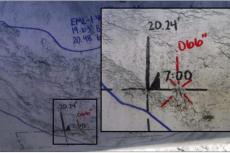

Real-time remote monitoring and risk management of oil & gas facilities subjected to natural hazards

Real-time remote monitoring and risk management of oil & gas facilities subjected to natural hazards

The term “natural hazard” is used to describe any natural pheno menon that might have a negative effect on humans and/or the environment. The natural hazards can be classified into two broad categorie s: geological and meteorological (e.g. landslides, volcanic eruptions, heavy storms, floods, droughts and high ambient temperatures). Furthermore,…

ptj-1-2020 Editorial

the Covid 19 pandemic has overwhelmed us all like a tsunami - unwanted, unanticipated and therefore completely surprising. It has plunged the global economy from a high into a deep crisis in a very short time. Nearly all areas of social and economic life have been affected and have to switch to standby or abort in the shortest possible time - or…

100km Pipeline Monitoring: Record Length For Intrusion And Leakage Detection

We demonstrate a record length of distributed acoustic fiber sen sing (DAS) for pipeline monitoring. Both intrusion (third party interference) and leakage can be detected. An ultra-sensitive architecture enables record length (100km for a single ended fiber sensing system or 200 km for sensing from both ends) detection while advanced…

Additional Functionalities Of Model Based Leak Detection Systems To Improve Pipeline Safety And Efficiency

The main purpose of a l eak detection system is of course the reliable and sensitive de tection and localization of leaks in a pipeline. Nevertheless certain systems such as those that are based on a pipeline model (e.g. E-RTTM based system, i.e. extended real-time transient model) deliver additional information of the pipeline operation and…

Advancements In Leak And Theft Detection Technologies

API 1175 discusses the requirements for continuous improvement in pipeline leak detection and the culture required for an effective leak detection program.

The most commonly used internal based methods for leak detection are flow balance, negative pressure wave and Real Time Transient Model (RTTM). Several papers have been written on each type of…

An Exploratory Data Analysis Of Pipeline Coating Degradation

Pipeline coatings can be constructed from a multitude of materials, all of which aim to provide a physical barrier between a pipeline and the external environment. Naturally, understanding the degradation characteristics of these different coating materials is critical, as with the onset of coating degradation comes metal degradation, i.e.…

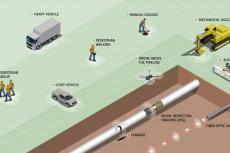

An Increasing Concern: Third Party Interference Damage On Buried Pipelines.

Encroachments on buried HP Gas pipelines represent 50% of accidents on pipelines world-wide. The consequences for pipeline owners can be critical, resulting in fatalities and injuries, but also economic cost: shutdown of refineries, damage to the environment, increased compliance etc. This is a huge issue for both types of pipelines:

• Older…

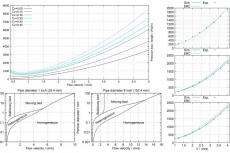

Challenges in the hydraulic simulation of slurry transportation through pipelines

The transport of solid particles in a gaseous or l iquid carrier fluid, usually referred to as slurry transport, is an import - ant technology in various industrial fields. Examples for slurry usage are dredging and mining processes, fer tilizer and cement production, desalination plants, the food and paper industry, sewage disposal and…

Construction Of Pipelines In Steep Terrain With Cable Crane Systems

Cable crane systems provide the solution when pipelines need to be built in inaccessible terrain. Pipes, construction material and equipment can be transported easily over demanding areas and be positioned at any point of the track. With a max. length of over 3.000 m and a payload of up to 20 metric tons material ropeways (cable cranes) can be…

Detection Of Non-Axial Stress Corrosion Cracking (SCC) Using MFL Technology

Many factors affect how and when line pipe wil l experience a pipeline integrity threat, including materials, vintage, environment and loading conditions. An integrity threat of particular interest is stress corrosion cracking (SCC). SCC is a type of environmental assisted cracking (EAC) that can occ ur in line pipe under a ver y specific set of…

Know Your Deposits – Novel Deposit In-Line Inspection Tool For Quantifying And Characterizing Solid Deposits

Pipeline pigging services in the oil & gas industry are of considerable mar ket size estimated to reach more than 14 billion USD by 2025. It is essential for the operator s to keep the lines open for smooth flow and the intelligent services are in focus to increase efficiency and cut the overall operational costs. Optimal pipeline cleaning…

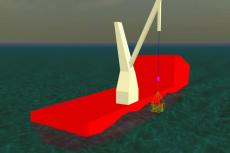

Motion Method Selection For Improved Accuracy Of Time-Domain Analysis For Subsea Installation

When installing subsea structures and pipelines, the ability to capture the worst case loading and limiting sea states during the installation analysis can improve safety offshore and l ower the operational risks. Therefore, it is important to select the correct analysis method to obtain the most accurate results.

Time-domain irregular wave…

Overcoming Challenges In Performance Validation Of Fiber-Optic Pipeline Leak Detection Systems

External Leak Detection systems based on distributed fiber optic sensors (DFOS) o ffer the exciting potential to significantly reduce the overall amount of spilled product before a l eak is detected and localized. As an external system, the validation of system performance and equally the verification of an operational installed system is a known…