Detection Of Non-Axial Stress Corrosion Cracking (SCC) Using MFL Technology

Many factors affect how and when line pipe wil l experience a pipeline integrity threat, including materials, vintage, environment and loading conditions. An integrity threat of particular interest is stress corrosion cracking (SCC). SCC is a type of environmental assisted cracking (EAC) that can occ ur in line pipe under a ver y specific set of conditions. First, the material must be conducive to corrosion, which in general is true for common grades of line pipe. Second, the material must be subjected to a corrosive environment. And finally, the material must be subjected to tensile stresses.

The most common appearance of SCC results in colonies of cracks parallel to the axis of the pipe. This is expected, as the principal stress due to internal pressure results in a hoop stress. The in-line inspection (ILI) industry has responded to this threat with crack detection technologies that are specifically designed to detect and size axially oriented SCC and other crack features. However, additional pipe loads associated with external forces, such as line movement, can introduce additional stresses, resulting in non-axially oriented SCC. Under these circumstances, the crack detection technologies specially designed for axially oriented cracking will not be able to accurately detect and size these features.

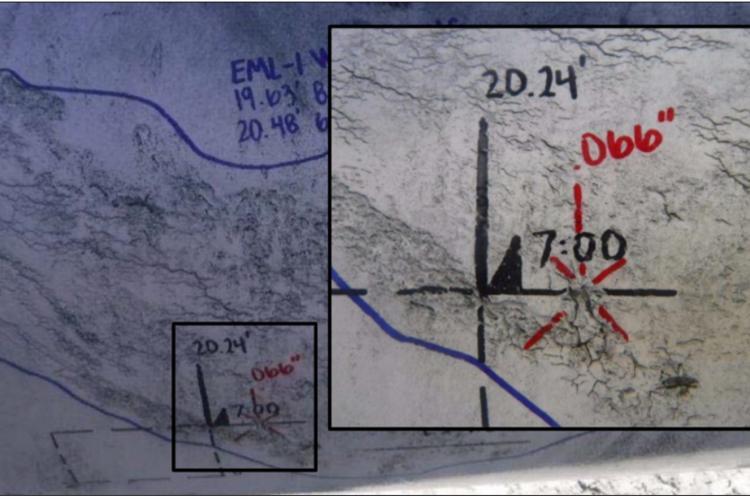

In response to this gap, research has focused on leveraging existing technologies that can infer the presence of non-axial SCC. Existing technologies can detect the presence of corrosion, determine the additional strain caused by pipe curvature and, given the right conditions, Magnetic Flux Leakage (MFL) technologies have demonstrated the capability to indicate regions with crack-like flaws.

This paper will review several case studies where the data from multiple data set (MDS) ILI tools combined with inertial mapping unit (IMU) technology to find regions where non-axial SCC might occur.