Revolutionising Pipeline Safety: Intelligent Weldment Inspection Decision Support System

The costs of pipeline failure are immense i.e. fatalities, environmental damages, loss of revenue and reputation. EGIG and OGP provides solid evidences and causal analyses of pipeline failures. PETRONAS has a structured methodology and system in eliminating pipeline failure. Nevertheless, failures do happen on newly constructed pipelines and those failures were due error in evaluating weldment inspection results.

Thus, there is an imminent need for industry to establish a robust approach and technology in addressing the issue. Currently, the industry is heavily dependent on human i.e. inspectors in interpreting weldment anomalies and mis-interpretation occurred resulted in pipeline failures and cost hundred millions of ringgit of opportunity losses.

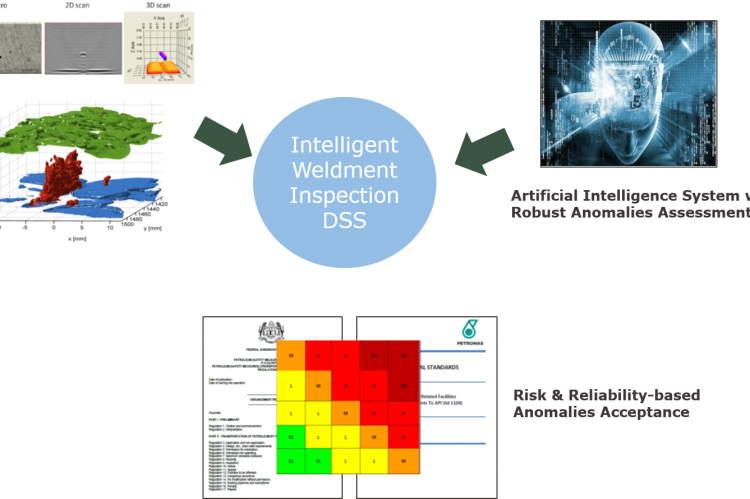

An intelligent welding inspection decision support system could significantly reduce human intervention and eliminate mis-interpretation. This paper will touch on the overall pipeline incident statistics worldwide as well as in PETRONAS. It will discuss on two critical management systems that PETRONAS employs to ensure pipeline system is designed, constructed, tested, operated and maintained safely and reliably i.e. the PETRONAS' Project Management System and Pipeline Integrity Management System. The ultimate would be discussion around the concept and inspired capabilities of an Intelligent Weldment Decision Support System.