Improvements of an Inspection Technique for Unpiggable Pipeline Diagnostics from Above Ground

There are thousands of unpiggable and challenging pipelines running through Europe alone. The integrity management of these pipelines requires nondestructive evaluation techniques, which can be applied without introducing inspection tools into pipelines.

Pipeline diagnostics shall, therefore, be executed from above ground. Indirect approaches such as DC Voltage Gradient (DCVG) survey or External Corrosion Direct Assessment (ECDA) can be used for this purpose. However, such approaches are characterized by distinct limitations, i.e., properties of soil (DCVG), or necessity of reference excavations (ECDA). Consequently, the latterly mentioned techniques can only be used for external corrosion and coating damage detection and not for information about a metal loss in the pipe wall.

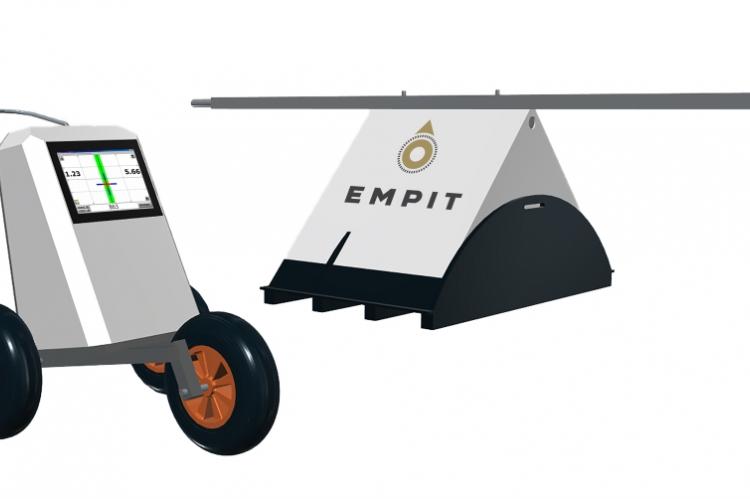

The presented Above Ground Inspection Technique (AGIT) has been developed to overcome limitations of DCVG, ECDA, and In-Line Inspection (ILI). Thus, AGIT is capable of localizing and categorizing external and internal metal losses in unpiggable pipelines. All crucial information of the pipeline will be given to the customer through only one inspection run. The Electromagnetic Pipeline Testing GmbH (EMPIT) holds all exclusive rights and assets of AGIT.

At first, the physical basics and technical principles of AGIT will be explained. Briefly spoken, the technique is based on above ground measurements of the magnetic field of a buried pipeline under test. Metal loss defects in the pipeline wall become detectable through AGIT as they result in measurable changes of the magnetic field at different frequencies. In addition to the magnetic field data, the pipeline’s depth of cover, the test current in the pipeline, and the chainage along the pipeline will be stored and used for further evaluation. Moreover, information on coating holidays based on registered local leakages of the test current and the presence of metal objects in the close vicinity to the tested pipeline will be highlighted and presented to our customers. Secondly, a review of performed inspection runs, including a comparison of detected features and their validation through excavations, is presented. It has been proved that AGIT demonstrates a high level of reliability in detecting pipeline defects. Lastly, the goals, approaches, and test results of improvements, achieved by a new development of the AGIT, including the method itself, the field inspection unit, and the evaluation procedure, will be discussed.