Flexible asset integrity capabilities by means of the vibroacoustic technology framework

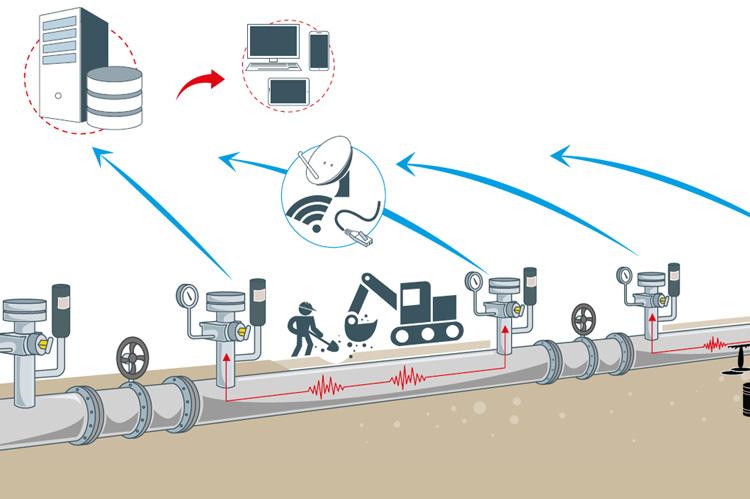

The vibroacoustic system (e-vpms®) was designed by Eni S.p.A to detect and accurately localize spillages/leakages in crude oil and finite product pipelines, although has shown over the years the capability of detecting a wide class of Third Party Interferences phenomena. The reason of this high sensitivity is ascribable to the physical-acoustic properties of the pressurized fluid in the pipeline. Events of spill generates a negative pressure transient into the fluid (i.e. acoustic signal) able to travel for tenths of kilometers inside the conduit.

Moreover, the interaction between an impact and the inner fluid is not direct; impacts are mainly responsible for the transmission of elastic energy to the metallic shell in terms of mechanical vibrations. The elastic wave-field travelling into the solid is transmitted to the internal fluid undergoing an acoustic conversion. Once converted in an acoustic perturbation, the signal can travel for several kilometers inside the pipeline.

Similar considerations can be done also in case of the vibration noise produced by a digging activity over the buried pipeline, right on top or nearby. The mechanical energy of the operation is transferred to the soil in terms of vibrations, towards the pipe shell and finally to the fluid. The energy transfer between soil and inner fluid follows a decay not simple to explain through standard attenuation models. To date, the e-vpms® has achieved a very high level of maturity, nevertheless R&D engineers are constantly working to improve the integrity monitoring system and to find new applicative scenarios.